خلاصہ

Extensive knowledge in designing and supervision of HVAC and Plumbing systems, developing BOQ's proposals and bid documents. Skilled in calculating peak loads for heavy industrial HVAC systems, Plumbing systems and modifying to new plant requirements. Demonstrated ability to handle multiple projects meeting deadlines with sound management skills.

پراجیکٹس

تجربہ

Project Supervisor Mechanical

• Supervision and monitoring of mechanical construction activities of the EPC Contractors to ensure that all mechanical construction activities are carried out safely and fully in accordance with the Company's HSE and technical requirements.

• Ensuring that the work is carried out on schedule, within budget, and to the specified quality requirements.

• To carry out regular HSE audits and inspections, both ad-hoc and formal, of the contractor's facilities and operations and to ensure that HSE standards are maintained at the highest levels.

• Prepare audit and inspection reports and ensure that action items are promptly followed up by the contractors. Issue Unsafe Act Reports as and when required and ensure that these are promptly followed up and closed out by the contractors.

• Ensure that appropriate safety procedures are implemented during the execution of the work, which will include the review of method statements as well as witnessing at site.

• Ensure that all materials used by the contractors are in accordance with the specifications.

• Monitor Mechanical activities and ensure adequate Contractor resources to ensure optimum progress of the work in the mechanical discipline.

• Implement the Company Quality Assurance Plans through the checking, witnessing and recording of the quality activities as described within the Plans.

• Witness all critical quality activities including hydro testing.

• Ensure that all construction and pre-commissioning activities are suitably documented to provide a smooth handover to the Site Commissioning Team.

• Monitor as-built drawing preparation by the contractors to ensure that these are accurate and produced on time.

• Review and comment on the contractor's planning related to mechanical activities.

• Liaise closely with Operations personnel, on a day-to-day basis, to ensure that they are kept fully informed of the contractor's activities and that appropriate Operations input is obtained during the implementation of the work.

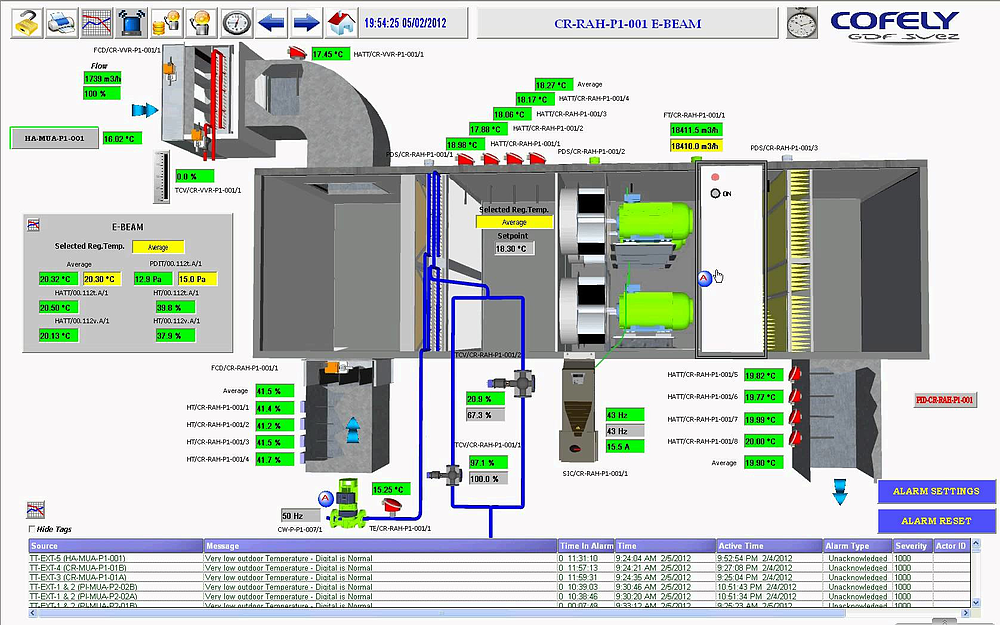

Project Engineer Mechanical HVAC

• Preparing Tenders, B.O.Q's, Schedule & Proposals for MEP Projects

which covers all engineering and financial aspects.

• Design, Estimation & Analysis for Mechanical Projects (HVAC, Plumbing & Fire Protection).

• Cooling load Calculations, Block load & Peak load as per ASHRAE-110 standards through (HAP-Carrier 4.8).

• Psychrometric Analysis of Projects.

• Designing of HVAC Equipment’s, Air Handling Units (Pharma Grade), Fan Coil Units,

Cooling Tower selection & Chiller Calculations.

• Designing of HVAC Ducting Layouts as per SMACNA & ASHRAE Standards.

• Ventilation System Design & Air Change rate calculations.

• Specialized in Designing Plant Rooms & Heavy Duty Power Generation Rooms.

• Specialized in Designing of Negative Pressure Isolation Rooms for Hospitals & Labs.

• Supervision of CAD Operators for preparation of Design Drawings.

• Co-ordination with Clients, Architects, Contractors, Manufacturers, & Suppliers.

• Making Inspections & Troubleshooting of HVAC & MEP Projects.

Project Engineer Mechanical

• Cost Estimation & Quotation making of MEP Projects.

• Preparing Load Calculation & Estimation by using (HAP-Carrier).

• Designing of HVAC Ducting Layouts as per ARAMCO, ASHRAE & SMACNA Standard for Projects.

• Calculation of Pressure differential & Pressure drop for Ducts, HVAC Equipment’s

& Air Duct Accessories Include (Volume Control Dampers, Diffusers & Grills).

• Selection & Designing of HVAC Equipment’s (Handling Units, Fresh Air units, Axial Fans, Cabinet Type Fans, Exhaust & Ventilation Fans) as per Consultant Requirements & Project aspects.

• Designing of Negative Pressure Isolation Rooms for Hospital & Laboratories.

• Preparing of Equipment & Material Submittals for consultant approval.

• Project Supervision & it’s execution as per estimated time line.

• Making Inspections & Troubleshooting of HVAC & MEP Projects.

Application Engineer HVAC

• Complete calculation of Air Handling Unit dimensions & Coil dimensions as per require CFM, Static Pressure other technical data.

• Making Quotations & Complete Designing of (Air Handling Units, Fresh Air units,

• Fan Coil Units, Cooling Towers, Cent. Cabinet Fans, Air slide Fans, Axial Fans & Heavy Duty Industrial, Exhaust & Ventilation Fans).

• Issuing of Job Card & Troubleshooting with manufacturing designs.

• Site Supervision during Duct & HVAC Equipment Installations.

• Final Inspection & making Test Reports.