概要

PEC Number # ELECT/76809.

I am an ambitious individual who is looking to broaden my career path. I am open to new challenges within the industry and am willing to work hard to reach my goals. I have the ability to lead and work with people-well as evidenced by my active participation in campus activities. I will be responsible from conceptualization to execution where all my knowledge and skills as an Electrical Engineer will put to test.

项目

工作经历

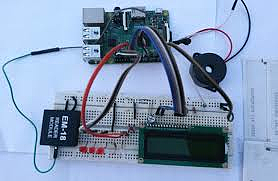

Research Assistant

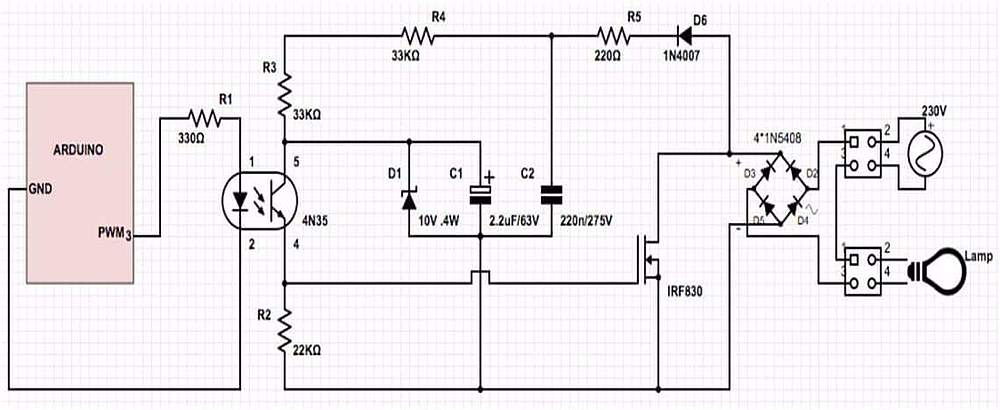

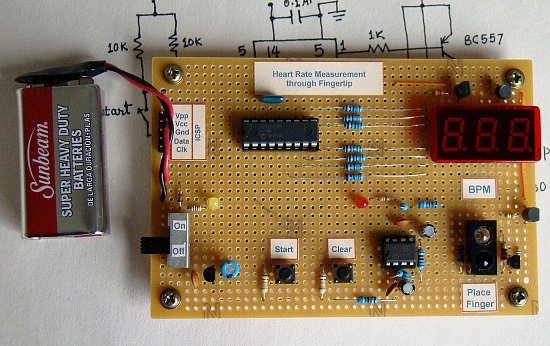

As a research assistant at EDCAS, my duty was to research and propose solutions for the given problems along with weekly work presentations. I worked on the Wireless power transfer project of NRPU (partially), Vaccine Dispenser project of UAE and 500-watt inverter for 400Hz frequency application

Internship

The three-week internship at PAC-Kamra was a great opportunity to see live testing and production of circuits used in JF-17 Thunder. I was in P & T (Production and Testing) department of APF (Aircraft Production Factory) where I learned basic PCB boards manufacturing and their different testing procedures. I also get to know there about the RADAR design and about the Battery Bank used in aircraft. My visit into world 8th standard clean room was another thing to be memorized.

Internship

Internship at PIA made me much familiar to the testing instruments and devices. I was specifically sent to the testing lab of PIA Electrical department where I polished my academic knowledge of Instruments and Measurements with practical experience. I learned about the basic battery features and the theory behind grounding the aeroplane after the flight. And basics of aeroplane aviation and parts.

Internship

My internship at PCSIR helped me to enhance my skills in troubleshooting of electronic circuits. I was in the RF department where many faulted PCBs from other departments come for testing and repairing. I also did work on PLC based Milk Pasteurization Machine which give me hands-on experience and some command on PLC.lk Pasteurizing Machine) and implement different logic on PLC.