概要

A self-motivated achiever having extensive experience of 6 Years in Production. Have ability to learn, plan, execute and work as a team leader and team player. Based on my engineering background and consonant interest, I aspire for a growing position where outstanding analytical and technical education can help to perk up the company’s profitability and give me a chance to polish my technical as well as managerial skill.

项目

工作经历

Production Engineer

Enter Description

Team lead Quality

Manage entire quality team, including engineers, supervisors, and quality inspectors

Handling of internal & external customer complaints and identifying the potential root causes by using different QC tools.

Plan work schedules and co-ordinate the activities of the incoming, In-process and final inspection

Daily problem analysis through Gemba meetings

Perform instruments calibration in-house

Implementation of quality management system (QMS), through documented procedures

Provide training to all quality department to enhance their skill level

Develop and maintain the SOP of quality department

Responsible to maintain the SQMDC activity and share the management through MRM

Responsible to check the system is flow as per designed SOP

Responsible for the HSE activities in plant

Make sure the weekly and monthly internal audits for maintaining system flow

Production Executive

Monitor and control the assembly line plan to meet the production target

Reduction in DPU (Defect per unit) by eliminating root causes

Conduct data analysis by using 7 QC tools to identify and reduce the nonconformance

Lead and train the subordinates on process control and troubleshooting

Tack time calculation and line balancing of Elantra & Sonata model to reduce the cycle time

Man power management of line for better efficiency

Minimize the waste in the operation to meet production objective

Identification of subsequent changes to facilitate the line by implementation of kaizan

Arranging different training programs to enhance the production efficiency

Make sure the proper implementation of quality standards on assembly line

Department leading member of 6s team

Part of ISO (9001-2015) team

Assistant Production Manager

Implementing production plan and ensure the production efficiency

Line Balancing by helping of IE (Industrial Engineering) team for smooth production operation flow

Responsible for the assembly and testing line

Man power management of line for better efficiency

Minimize the waste in the operation to meet production objective

Responsible for suggestion and Kaizen activities for production floor

Arranging different training programs to enhance the skill level of line member

Make sure the proper implementation of quality standards on assembly & testing lines

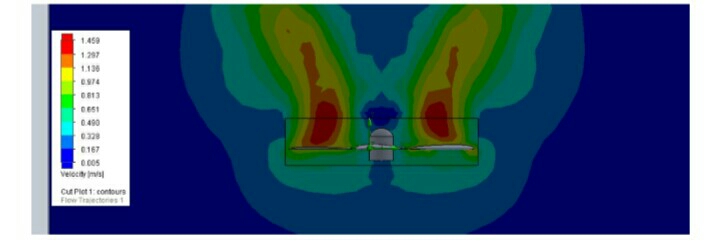

Production & Development Engineer

Preparing and implementing action plan effectively to maximize overall equipment efficiency of production machines.

Troubleshooting and solving technical problems related to production floor Utilization of manpower accurately

Minimize the waste in the operation to meet production objective

Responsible for suggestion and Kaizen activities for production floor

Arranging certain training program for labor and production shop floor to enhance the production efficiency.

Responsible for 5s activities.

Lead and train the subordinates on process control and troubleshooting

Continually improvement in the process to ensure error proofing, reduction in nonconformance and enhancing the process capability

Ensure proper implementation of Total Productive Maintenance including Predictive Maintenance, Preventive Maintenance and Periodic overhaul.

Calculate the Overall equipment effectiveness (OEE) of each machine to evaluate the performance of the operation.

Responsible for new development in organization

Planning and control of new development

Maintain drawings and drawing distribution ledger

Responsible for QAV (Quality Assurance Visit)

Responsible for initial production lots (IPP)