概要

I am a well-versed professional Mechanical Engineer with a comprehensive knowledge of vehicles and pressure vessels. 5 years of experience at Multan Metro Bus Service, signifying in diesel engine spares and assemblies. My Expertise includes troubleshooting, fault diagnosis, repair, and workshop management. I am focused on teamwork, analytical and interpersonal skills. 2 years of detailed engineering experience in awarded Pressure vessel projects.

项目

工作经历

Mechanical Engineer

• Providing operation and maintenance services for the client's fleet (Punjab Mass Transit Authority)

• Streamlined repair and service operations, ensuring adherence to manufacturer's standards; reduced customer complaints by 40% and improved customer satisfaction ratings by 15%.

• Led process improvement initiatives that resulted in a 25% increase in operational efficiency.

• Scheduling and assigning jobs to appropriate service personnel considering the nature of the repair

• Played a pivotal role in enhancing fuel efficiency by a remarkable 15%.

• Streamlined breakdown recovery processes through the implementation of lean methodologies, resulting in a 25% reduction in average resolution time.

• Technical handling of maintenance has resulted in a noteworthy reduction of up to 20% in associated costs.

• Assessing the cost of damage in consultation with the supply chain upon receipt of the damage report

• Maintenance of workshops to ensure that safety standards have been implemented for all service tools and equipment and incident ratio is 0 %.

Mechanical Design Engineer

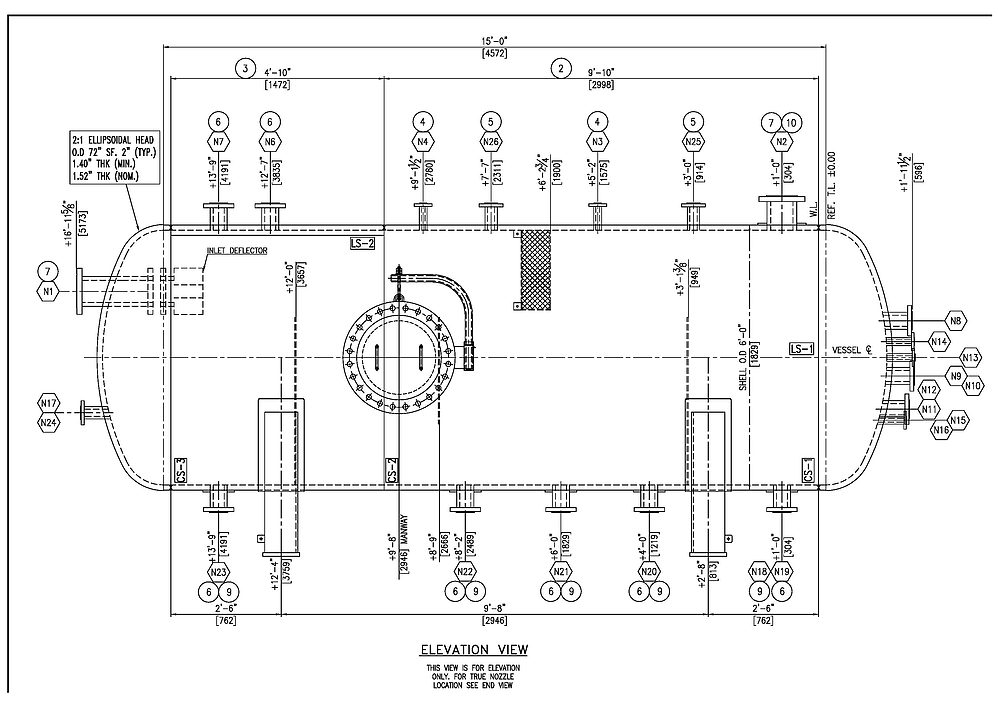

• Design and development of pressure vessels and heat exchangers by using PV Elite

• Development of mechanical piping and instrument diagrams (P&ID’s) using Auto CAD 2018

• General arrangement drawing of all kinds of vessels, re-boilers, exchangers and tanks as per relevant code

• Preparation of detailed fabrication drawings of the vessel’s internal and external attachments

• Generate bill of material lists and man-hour calculations

• Standard tolerance drawings & as-built drawings

• Design and development of pressure vessels with ‘U’ and ‘R’ stamp

Junior Engineer Workshop

• Consistently evaluated and revised maintenance schedules and plans to guarantee maximum efficiency.

• Ensured the prompt delivery of replacement parts by effectively coordinating with suppliers.

• Implemented quality control measures and reduced rework by 30%.

• Enhanced operational efficiency and productivity through the implementation of improvement strategies.

• Oversaw project team of up to 100 members and ensured their safety in the workplace.

• kept meticulous records of all maintenance activities, encompassing repairs, replacements, and inspections.