概要

F o r w a r d T h i n k i n g – R e s u l t O r i e n t e d – C o m m i t t e d

Energetic young and self-motivated with good communication skills. A creative individual with an insight for change and a strong ability to adopt latest technologies

Experience

Project Engineer

Darco Water Systems Sdn. Bhd

Jan 2018 - Present Pakistan

Assistant Manager (Technical)

Business Dynamics Pvt Ltd

May 2017 – Present Pakistan

Manager (Technical)

Milestone Engineering Pvt Ltd

May 2017 – Dec 2017 Pakistan

Assistant Manager (Technical)

Pollution Engineering Pakistan Pvt Ltd

December 2015 – May 2017 Pakistan

Intern

Oil & Gas Development Company Limited (OGDCL)

November 2015 – December 2015 (1 months) Islamabad

As an internee it was my responsibility to learn as much as I can from the spectacular experience being given to me by this organization So I established deep understanding regarding the working and ongoing processes of Process and plant sector.

- Practically experiencing the theoretical knowledge in API (especially heat exchangers, pumps and valves).

- Rotation through different departments helped to gain knowledge regarding job of Mechanical Engineers

Intern

Toyota Motors Islamabad

June 2013 – July 2013 (1 months)

To observe the working environment and try my best not just to blend in but to make this experience count. I was given a chance to study the areas of Manufacturing,Assembling, Casting, Engine and to make the best out it by applying the knowledge and norms extracted from them to use in later professional life.

项目

工作经历

Project Engineer

• EPC of Waste Water Treatment Plant of MBR technology at PKLI Lahore Pakistan (Capacity 1600 cubic meter/day)

• PC Mirpur-AJK Packaged plant MBR technology (Capacity 40,000 GPD)

The Wastewater treatment plant are constructed to treat sanitary waste from PKLI hospital. The plant will be located next to the PKLI dialysis center. The main source of effluent is wastewater from hospital, university and residential complex contains organic particles (feces, hairs, food, vomit, paper, and fibers), soluble organic material (urea, proteins, and pharmaceuticals), inorganic particles (sand, grit, and metal particles), soluble inorganic material (ammonia, cyanide, hydrogen sulfide, thiosulfates) and other substance. Wastewater from the hospital flows by gravity via sewer pipeline into inlet sump, where they will be lifted into EQ Tank, Anoxic tank & Aeration Tank followed by MBR system. The use of MBR system enhance treated water quality standard for reuse in horticultural activities.

The wastewater treatment plant consists of inlet sump where wastewater flows by gravity through coarse screen into collection sump. Two unit of submersible pump will lift the water through fine drum screen and be stored in Equalization Tank. At High Level, two pumps will transfer the water into Anoxic tank for denitrification process. Existing from Anoxic tank is two units of Aeration & MBR system running in parallel. MBR consists of membrane with pore size 0.4micron. Suspended solid and portion of the bacteria population will not pass through the membrane. MBR can effectively separate solid from liquid, excellent product water, almost no suspended solids or turbidity, completely replacing the secondary sedimentation tank.

Assistant Manager (technical)

• Polymer additive (d2w and d2p) awareness and distribution for antimicrobial pipes and oxo-biodegradable plastics

. oxo-biodegaradtion of plastics, antimicrobial pipes, antimicrobial paints and coatings for the safety purpose of environment.

Manager (technical)

• Supervision of Effluent Treatment Plant and Sewage Treatment Plant

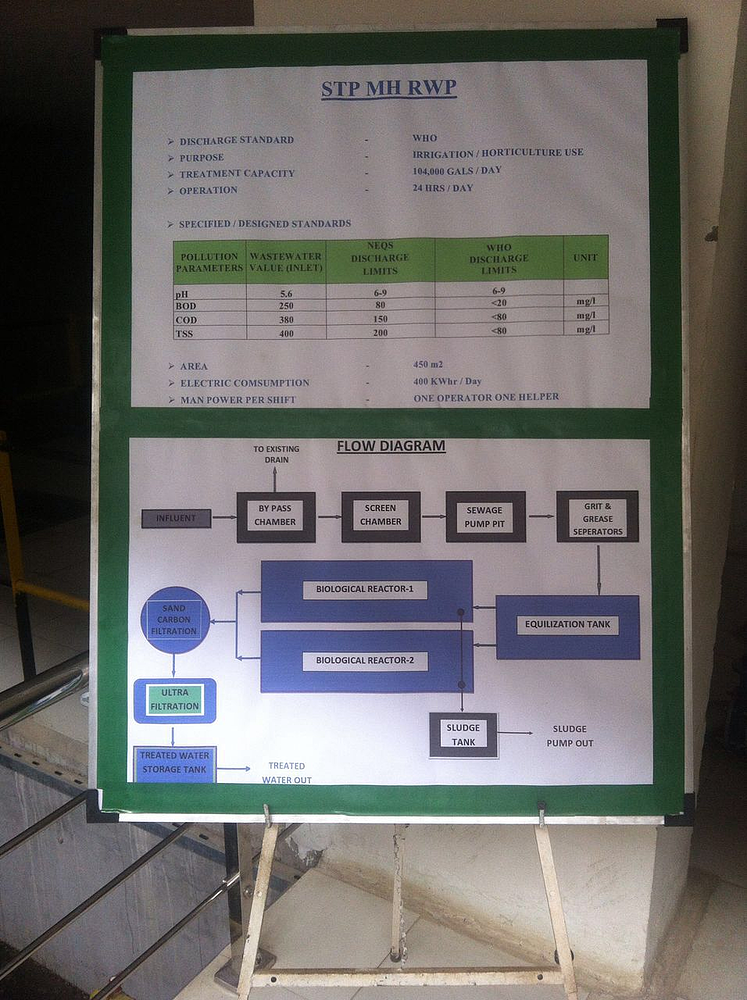

• OGDCL Qadirpur Field (STP Capacity 182 cum/day)

• TAVTA Lahore (ETP Capacity 2,500 G/day)

ASSISTANT MANAGER (TECHNICAL)

• Supervision of Sewage Treatment Plants

• Military Hospital Rawalpindi Pakistan (STP Capacity 460 cum/day)

• Combined Military Hospital Rawalpindi Pakistan (STP Capacity 460 cum/day)

Basically this company is Malaysia based and used to build waste water treatment plants in which waste water is treated by different processes such as using:

Mechanical screen for removing large material from water such as polythene bag etc.

Sckum Skeamer used for removing grease and oil from water.

Grit separator is used for removing small grits from water.

Aeriation is done with the help of blowers to break down the organic matter dissolved in water.

Sequence Batch Reactor is used for removing sludge from water.

Sand filter,Carbon filter and filtration unit is used for making water transparent.

and at the end chlorine dozing is done.

After that treated water used for irrigation,parks etc.recently we have installed two plants in MH and CMH hospital.Other than that we have also installed the plants in DHA,Bahria town,Mari petroleum,Quetta,Gawadar.