概要

To become an expert in the field of Electrical Engineering and control systems having hardware and software traits. I want to be exceptionally creative, versatile and Problem-solving skilled person that deals in all formats from design and engineering level to the management level.

I have done various independent projects including design and commissioning of end of line conveyor system, feed water control systems of RO plants. All these works demand both the technical and management skills to fulfill the required tasks.

项目

工作经历

Automation Engineer

Perform meetings (from Kickoff till Control narrative finalization) with clients to initiate the designing (layouts, P&ID, Electrical drawing) of project.

Prepare the cause and Effect sheet, I/O list, BOQ of the project.

Perform R&D on core issues (mostly related with establishing communication between different modules), develop mockups to assure the client existing problem’s solution.

Develop the controllers program using IEC 61131-3 standards and P&ID with symbolization ISA.5-1.

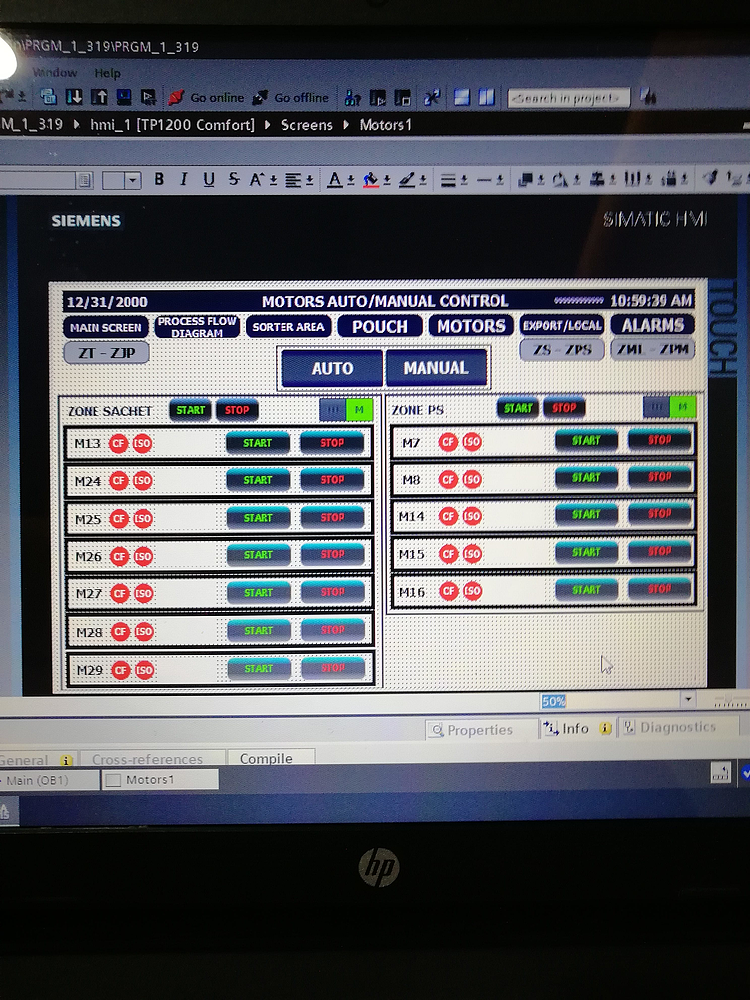

Develop the Siemens based PLC program in Ladder Logic using the software TIA Portal V14, and design HMI using WinCC Flexible. Establish the communication between siemens module (S71200/1500) with SICK CLV series barcode scanners using Profinet protocol and Energy meter (LM737) using Modbus RTU.

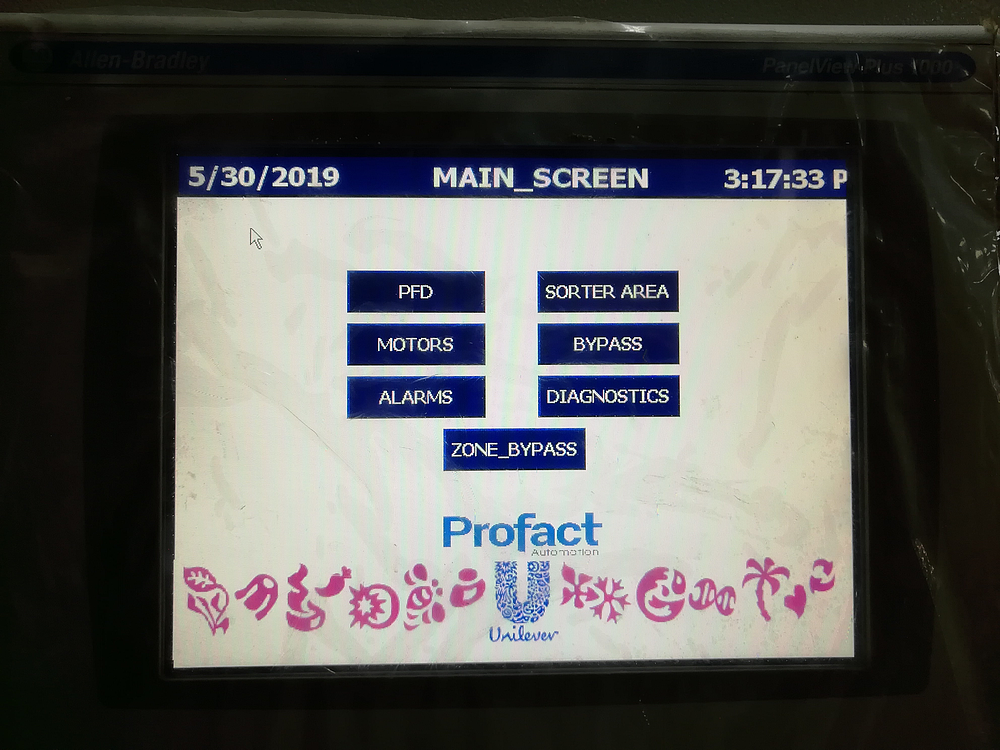

Develop the Rockwell based PLC program using RSLogix 5000 software and design HMI using Factory Talk View Machine Edition.

Build the Beckhoff PLC program using the software TwinCat 2 and develop the visualization upon CP6606-0001-0020 built in panel PC.

Perform FAT (Factory Assessment Test) of panels before the commissioning and SAT (Site Assessment Test) as per client allocated procedure.

Prepare the FDS (Functional Design Specifications) after the project’s completion.

Keep in contact with client as the company policy and resolves after sales and commissioning project issues.

Log the day to day activities to maintain good KPIs and report them to manager.

Assistant Application Engineer

• Develop the Siemens based PLC program in Ladder Logic

using the software Portal V14, and design HMI using WinCC

Flexible.

• Develop the BOQ (Bill Of Quantities), electrical drawing used

in the panel, prepare the FDS (Functional Design

Specifications) after the project’s completion.

• Perform site visits to evaluate the problems of clients and

provide the solutions.

Trainee engineer

I had worked as a trainee engineer where my key responsibilities were.

Assured the proper working of Genset and the functioning of rotor, stator, and windings.

Monitor the protection of transformer thoroughly by checking the proper functioning of relays which includes Buckle Relay, Tape Changer Relay and checked the amount of Silica gel to assure the vacuum in the transformer.

Monitor the overall plant operation on the specific designed HMI’s with proper coordination with the operations officer.