概要

Being Chemical Engineer, have 1 year experience at Attock Refinery Ltd of different plants including CDU, VDU, DHDS

& HYU with major responsibility to Handle & troubleshoot all type of emergencies and also have 9th months dyeing

experience at Style Textile Ltd to develop production plan. Being professional, I am self-motivated,

determined & goal Oriented with strong interpersonal and Intrapersonal skills.

项目

工作经历

Management Trainee Engineer (Chemical)

My Responsibilities:

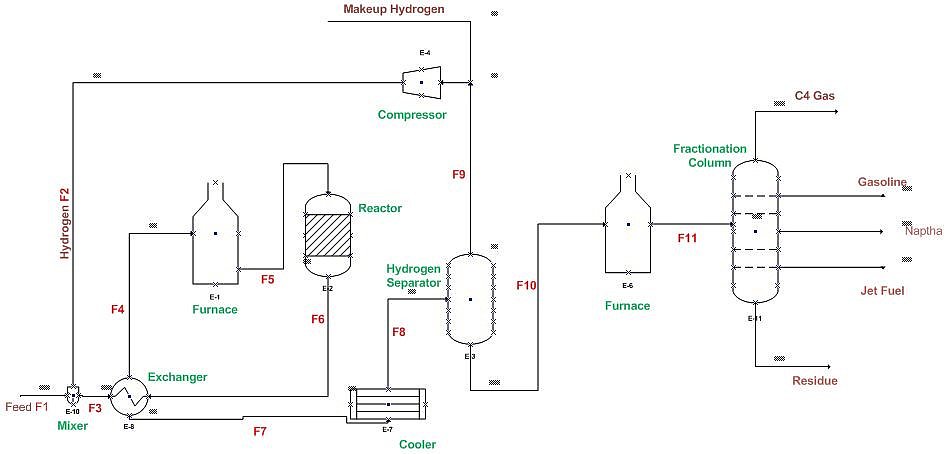

o Detailed process sequence, understanding native P&IDs, PFDs, and control philosophy of CDU, VDU (Continuous,

Vacuum Distillation), DHDS (Diesel Hydrogenation Desulphurization) & HYU Units

o Suggested a modification to DM (operation) of area 1 that Contaminated Diesel in feed storage tank of DHDS

Plant can be transferred to Slope Oil Tank using existing pump & piping

o Managed the all jobs (Pig decoking of Heater, Cleaning of all exchangers, Installation of new plates of stabilizer

etc.) under supervision of senior Engineer during Annual Turnaround of Heavy Crude Distillation Unit (10000

BPSD)

o Updated the P&ID, 3rd revision, of HCDU within 15 days

o Defined and supervised the maintenance jobs after emergency shutdown of Vacuum side of HCDU

o Troubleshoot & Handle all emergencies under the supervision of Shift Engineer with the coordination of operators

to avoid any unsafe condition for personnel & plant

o To ensure smooth start up and shut down activities of plant

o Calculated the efficiencies & Heat duty of Fired Heaters & Heat Exchanger

o Draw the P&ID of HCDU & DHDS at MS VISIO

o Delivered 3 days lecture to interns & apprentices about Vacuum side of Heavy Crude Distillation Unit

Certification & Workshop:

o Certified by HSE&Q-ARL, after 3 days basic safety training

o Attended 2 days training about Heater operation

o Practiced in 1 day mock drill to extinguish the fire.

o Voluntarily joined one day training of Rescue 1122 that held in ARL RWP.

o One week training of Oil Movement 1 & 2

o Voluntarily joined one week training of OTS (Operational Training Simulation)

Management Trainee Officer

My Responsibilities:

o Used of Oracle, Made a production plan for dyeing department according to Dyeing Machine Capacity, Colors &

fabrics quality.

o Ensure the quality & quantity of dyes for the smooth operation.

o On regular basis attended the quality control meeting to enhance the quality of dyeing.

Internee

Century Paper and Board Mill Ltd is a part of Lakson group and leading company of paper sector in Pakistan. It has 7 sections of Paper and Board manufacturing.

• Technical Skills: learned the basic layout of Board manufacturing with precautionary measurements and working of different equipment’s i.e. Pulper, Pumps, Valves etc. and draw the P&ID on MS VISIO.

• Research Skills: Calculated the utility requirements for manufacture of 1 ton Board and analyzed the effluent stream of PM7 section for its effective used.