概要

Results-driven and dedicated with wide-ranging experience planning and leading operations involving small- to medium-sized manufacturing environments. Track record devising, evaluating, and implementing continuous process improvements to minimize waste and reduce costs while maximizing quality and yield. Establish effective quality control and safety programs, encouraging proactive participation across the manufacturing floor. Excellent communicator; success building cohesive teams focused on production goals, safety, and throughput.

项目

工作经历

Production Manager

Manage the flow of production and quality control and develop strategies to improve quality and overall flow of production of Paddy to Steam/Sela, husking, and Processing.

Responsible for the operation of the plant in order to meet key measures in the operating plan.

Responsible for the development and implementation of operational budgets.

Assist in the planning and performance of preventive and corrective maintenance.

Maintain good communication and good relationships between company owners and employees.

Organize workflow to meet specifications and deadlines.

Monitor and oversee production process to resolve issues.

Planning and organizing production schedules

Organizing the repair and routine maintenance of production equipment

Supervise and evaluate the performance of production personnel (quality inspectors, workers etc.).

Determine the amount of necessary resources (workforce, raw materials etc.).

Approve maintenance work, purchasing of equipment etc.

Ensure output meets quality standards.

Determining quality control standards

Liaise with other managers to formulate objectives and understand requirements.

Develop a customized and concise processing report to ease the understanding of rice processing and its output.

Develop a customized and concise annual maintenance schedule for plant prevent maintenance.

Organizing relevant training sessions

Supervising the work of junior staff

Estimating, negotiating and agreeing budgets and timescales with suppliers and managers

Production Manager

Manage the flow of production and quality control and develop strategies to improve quality and overall flow of production.

Responsible for the operation of the plant in order to meet key measures in the operating plan.

Responsible for the development and implementation of operational budgets.

Assist in the planning and performance of preventive and corrective maintenance.

Maintain good communication and good relationships between company owners and employees.

Organize workflow to meet specifications and deadlines.

Monitor and overseeing production process to resolve issues.

Planning and organizing production schedules

Organizing the repair and routine maintenance of production equipment

Supervise and evaluate performance of production personnel (quality inspectors, workers etc.).

Determine amount of necessary resources (workforce, raw materials etc.).

Approve maintenance work, purchasing of equipment etc.

Ensure output meets quality standards.

Determining quality control standards

Liaise with other managers to formulate objectives and understand requirements.

Develop a customized and concise processing report to ease the understanding of rice processing and its output.

Develop a customized and concise annual maintenance schedule for plant prevent maintenance.

Organizing relevant training sessions

Supervising the work of junior staff

Estimating, negotiating and agreeing budgets and timescales with suppliers and managers

Stock Auditor

Protect against fraud and theft of the organization's assets

Make recommendations on how to improve internal controls and governance processes

Objectively review an organization's business processes

Visit the Branches and Check the Stock.

Check the Branches Atmosphere.

Maintain the internal audit reports and submit to G.M.

Plant Manager

Planning and organizing production schedules

Estimating, negotiating and agreeing budgets and timescales with clients and managers

Determining quality control standards

Overseeing production processes

Organizing the repair and routine maintenance of production equipment

Supervising the work of junior staff

Organizing relevant training sessions

To look after Processing of Pet Bottles and Flakes.

Coordinate the overall manufacturing process including personnel and equipment.

Manage the flow of production and quality control and develop strategies to improve quality and overall flow of production.

Responsible for the operation of the plant in order to meet key measures in the operating plan.

Responsible for the development and implementation of operational budgets.

Assist in the planning and performance of preventive and corrective maintenance.

Maintain good communication and good relationships between company owners and employees.

Factory Manger/ Admin Manager

Factory Manager in Midtrans Group of Companies

Manage the Food Safety/Quality Team, assuring that the Quality Supervisor is developing staff and utilizing them for the greatest effectiveness within the department.

Lead the Food Safety/Quality Team in the development, implementation and maintenance of the food safety and quality systems

Overseeing management of the documentation system, investigations, root cause analyses, and corrective actions.

Ensure compliance to international and federal food safety standards (including, but not limited to FSMA, FDA, USDA and interagency requirements.)

Ensure the organization’s processes and systems are adequate to implement, achieve, and maintain BRC certification.

Support with periodic HACCP reviews, implementation of foods safety/quality data collection records.

Management of documentation filing, internal auditing and management of the communication of quality information both internally and externally.

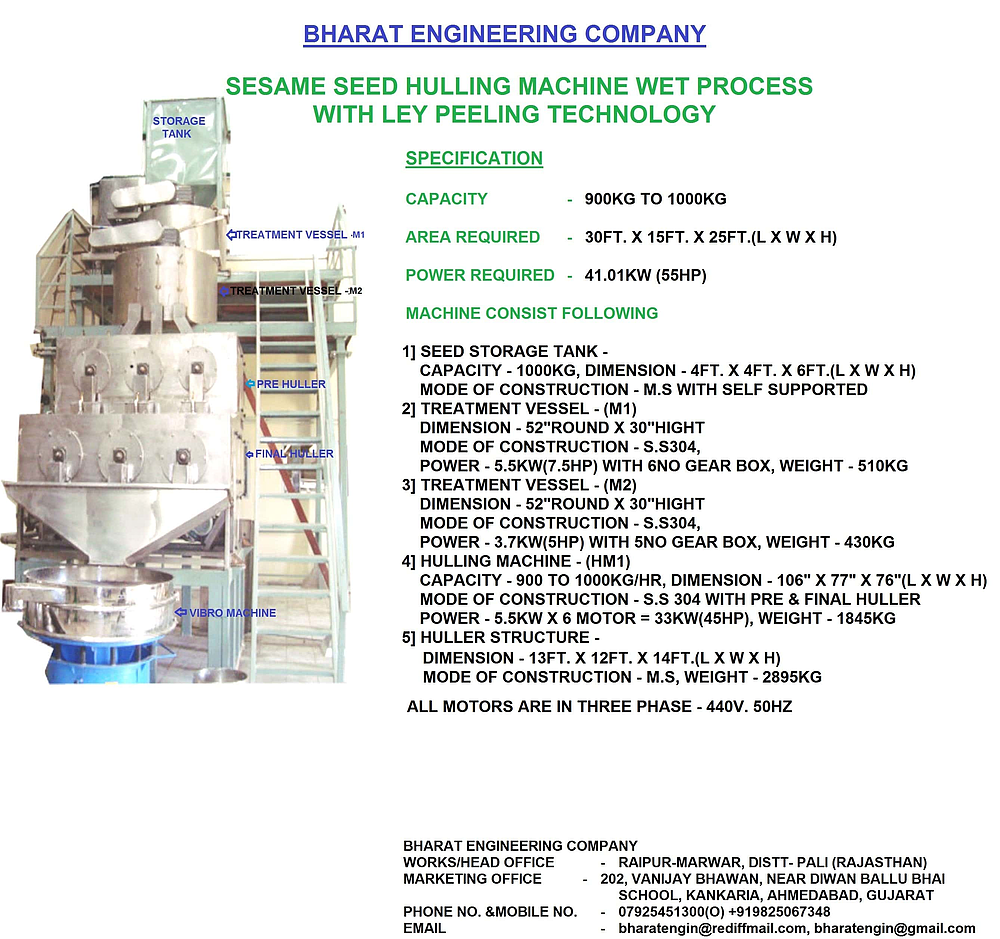

To look after Processing of Rice, Sesame Seeds, Hulled Sesame Seeds, Pluses, Almonds, Walnuts & Raisins etc.

Effective manpower utilization and Production planning.

Meeting production targets with prescribed norms of raw material.Online quality control.

Technical & Q.C. Manager

Understanding customer expectations of and needs from a product.

Developing quality control processes.

Designing product specifications.

Ensuring products are designed with adherence to legal and safety standards.

Supervising staff and monitoring production standards.

Examining the quality of raw materials that are used in production.

Monitoring and evaluating internal production processes.

Evaluating the final output of products to determine their quality.

Rejecting products that fail quality standards.

Engaging with customers and gathering product feedback.

Reporting to upper management on quality standard issues.

Improving production efficiency and managing waste.

Quality Controller

Quality Controller for Rice, Sesame Seeds, Yellow Maize, Almonds, Chick Peas, Raisins Pulses.

Inspecting output samples using industry-appropriate methods, such as comparing to standards, measuring dimensions and examining functionality

Checking that the assembly or production line adheres to standards and procedures and complying with legal requirements

Recording inspection results by completing reports, summarizing re-works and wastes and inputting data into quality database

Training the production team on quality control measures to improve product excellence

Proposing improvements to the production process

Monitoring the use of equipment to ensure it is safe and discard any that do not meet requirements

Updating job knowledge by engaging in educational opportunities and regular training

Keeping measurement equipment operating accurately by following calibration requirements and calling for repairs

Helper and Plant Operator

1 year Rice and Sesame Seed Processing Plant Helper and after 1 year Promoted to Plant Operator.