概要

A profoundly motivated and ambitious individual, alongside excellent communication and management skills and effective coding aptitude, seeking to pursue a career in the leading organizations. With a search-oriented nature, creative personality, leadership qualities and an educational foundation in Electrical Engineering with major in Electronics, looking forward to enriching my professional experience.

项目

工作经历

Assistant Manager

Style Textile is a 25,000 plus people organization in Sports Fashion Industry and is producing high end sports fashion garments for world's renowned brands like Nike & Adidas. MAIN RESPONSIBILITIES:Bring innovation by implementing different projects related to automation and Artificial Intelligence.Analyse the problems and implement engineering solutions to smooth the production process.Oversee the process of production including quality, audits and shipments and manage a team of 120+ people.

ACHIEVEMENTS:

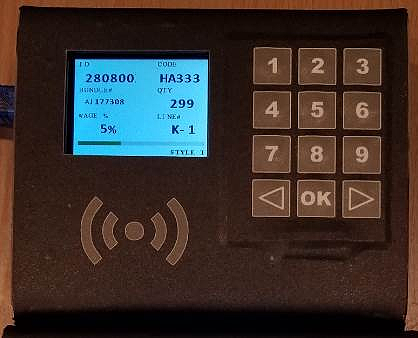

Designed a real time Production Monitoring Device (Using Arduino Mega 2560, ZigBee Xbee S2C, RFID and HMI display) after analyzing the problems being faced in Production Department. This device performs the following tasks:

-Monitors the performance of every operator and gives his/her real time          efficiency.

-Real time data management.

-Gives target to every operator along with the time limit to complete it.

-Time losses are monitored, which helps the management to eliminate the        causes and improve efficiency.

-If there is any machine fault, the operator can call the specific mechanic by       pressing a key on device and mentioning the fault. The time taken to repair       the fault will also be monitored.

Implemented a project to convert a simple LCD into a Smart TV using Raspberry Pi with the following functions:

-Starts the specific browser on auto boot and can be accessed remotely          from anywhere instead of dedicating one PC for one LCD. This project can        help the company save a lot of money.

Designed a real time Machine Monitoring Device that keeps us updated about

- Machine’s OFF state.

- Machine’s ON but IDLE state.

- Machine’s working state.

With the help of this device, the textile industries can know how many machines are being utilized per day and for how much time. We can also know the machines that are not in use at all andquestion about them.

Automation of 5 Card System.

Automated all the appliances of Production Units and controlling them with the help of application, motion sensors and voice recognition.

Intern

Work along with Assistant Manager on Auto Satellite Navigation and understand the concepts.

▪ Understand and implement different algorithms of image processing using MATLAB.

▪ Implementation of Facial Recognition Algorithms.

Head Organizor

Conducted a 5 day workshop on “Introducing Sustainable Energy Related Technology” to School Students.