خلاصہ

1) ULTRA PACK (PVT.) LTD

(AM - QHSE and Compliance (April 2019-Present))

Manufactures AD Star Poly Propylene sacks for various companies like Kohat Cement, Bestway Cement

HSE domain

- Assisted in the development of Inspection checklists and Work Instructions to contain COVID-19.

- Reporting COVID-19 violations to management

- Eliminating avoidable incidents and improving plant safety

- Conduct incident investigation, highlight root causes and make recommendations for improvements.

- Organizing Quality and HSE trainings on regular basis

QA/QMS domain

- Assisting in development of SOPs, formats and work instructions for all other departments to achieve ISO certifications

- Working on process improvement of departments - extrusion, coating, printing, weaving using lean tools (Process flowchart, time and motion study)

- Involved in risk assessment by investigating corrective action reports Working on ISO 17025 certification

- Ensuring equipment calibration and working on purchase of Master Calibration Equipment

- Ensuring quarterly environmental monitoring and reporting to local EPA office

Miscellaneous (CSR, others)

- Fulfilling department stationery demand by filling requirements sheet and Store follow-ups

- Maintaining all types of departments inventory by assisting in PR, following-up and dispersing in a proper way

- Planning of events and activities reference to specific days (World Quality Week, Annual Dinner)

- Coordinating with relevant vendors and generating CS Involvement in Technical and Management Review meetings

2) AMAL ACADEMY (Lahore, Pakistan) Career-Prep Fellow (January 2019 March 2019)

Education startup funded by Stanford University that teaches professional skills to students and corporations

- Communication Completed a competitive written application and interview process to be selected from over 3000 applicants for intensive 3-month Fellowship funded by Stanford University

- Skills development Investing 150 hours to develop business skills (e.g., communication, leadership, problem solving, teamwork, etc.) that will help me make a deeper impact on the job.

3) MILLAT TRACTORS LIMITED (Sheikhupura Rd, Lahore) Internee (July 2017 August 2017)

Manufactures internationally acclaimed tractors, Diesel Engines, Diesel Generating Sets other agricultural equipment under Massey Ferguson

- Watched how work is done on a production line in Tractor Assembly Plant

- Observed how complex machining operations are performed on engine parts

4) PAK ELEKTRON LIMITED (PEL) (Ferozepur Rd, Lahore) Internee (June 2017 July 2017)

Manufactures different types of Electrical Equipment Home Appliances (mostly related to HVAC)

- Team Work Worked in group of 5-6 internees

- Practical Exposure Observed how theoretical concepts of HVAC are applied practically in industry worked on project to increase effective output of deep freezer plant

5) PAKISTAN RAILWAY WORKSHOP (Mughalpura, Lahore)

Internee (July 2016 August 2016)

Workshop where rail engines are prepared and repaired

- First exposure of industry internship gave me insight and motivation to prepare myself for future career

- Visited different workshops of locomotive, carriage wagon shop

پراجیکٹس

تجربہ

AM-QHSE

Internee Engineer

It was different type of internships in two ways.

1) I got to know basic infrastructure of industry. Spent more time inside offices & saw how office work of engineering related products is done.

Had in depth review of departments including Production, Maintenance, Marketing, Sales & Quality.

2) Got to know basic working of batteries used in cars, tractors, UPS, solar systems. Spot differences in their Amp-Hr Rating & differences in their production.

Internee Engineer

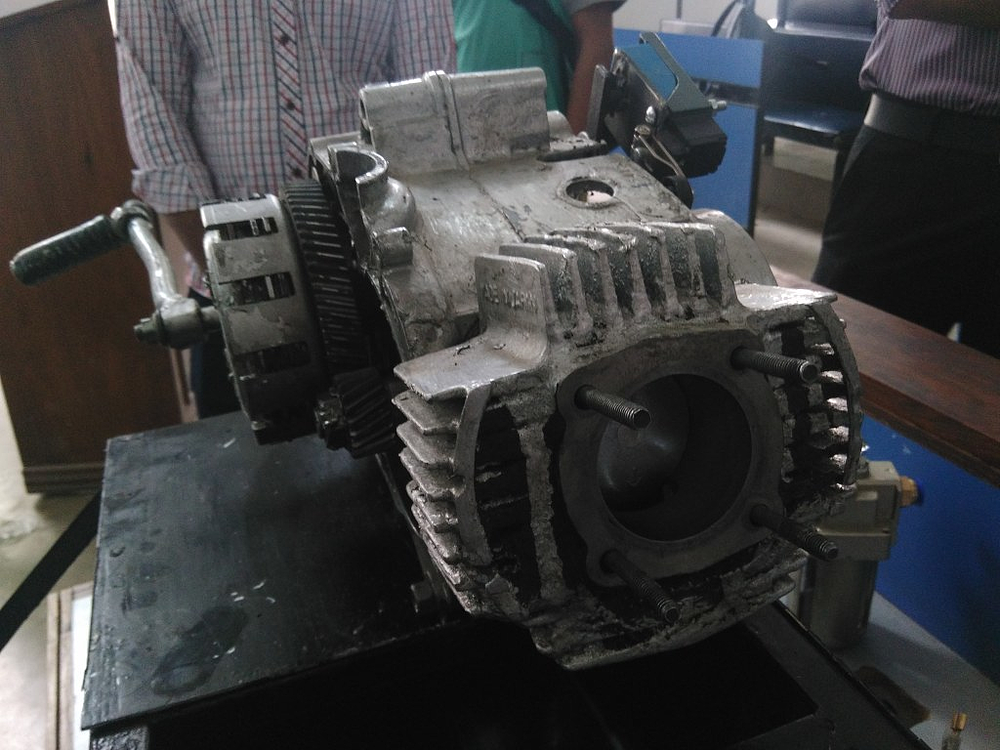

During my internship in M.T.L, I visited

1)Engine Assembly Plant, where assembly of diesel engines is done

2)Machining department, where machining of casted components (obtained from Bolan Casting Limited(BCL)) is done

3)Tractor Assembly plant, where complete assembly & testing of Millat tractors is done.

This internship was a useful experience. I have gained new knowledge and experiences.I got insight into professional practice.

Mechanical Intern

During my 4 weeks internship at Pak Elecktron Ltd, I along with my group members worked on a project

"To improve effective output of deep freezer section"

We did time study & identified major reasons of time lag & suggested our supervisor how to take out maximum output using minimum input in shortest time.

Also, I visited different sections(Dispenser, Refrigerator, Air Conditioner) & viewed different processes in their assembly.

Internship

During my stay in Pakistan Railways, I visited two workshops.

1)Locomotive workshop:

-Diesel Section (Assembling Diesel Engine)

-Millwright Shop (Various Types of cranes, weighing balances, chains)

-Tool shop (Milling, Lathe, Die, Boring, Milling Machines)

-Foundry section (Brass Foundry , cupla section)

2)Carriage and Wagon workshop:

-Spring Section (Leaf Spring & Coil Spring)

-Machining Section (Machining operations on various parts)

-wheel section(preparation of wheels)

The internship was a useful experience. This internship has given me new insight and motivation to prepare myself for future career.