خلاصہ

Result-oriented young professional adept at determining and resolving complex issues in the construction, operation and design. Seeking career opportunities in an organization where practicality and professional growth is promising; with managerial supervising or administrative responsibility.

پراجیکٹس

تجربہ

Design Engineer

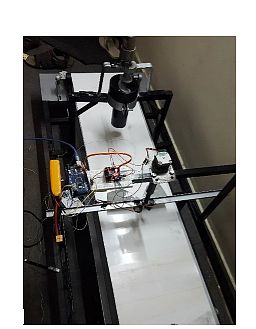

Wind Turbine Blade Washing Rig Project (On Going):

Worked with the team which developed indigenous turbine blade washing solution, successful implementation of which will result in approximately six GWh gains in annual production ($0.75 million gain in revenues) for each 50 MW Project.

Devised concept of designing Blade Washing Rig housing Pumps, Laminar Flow Nozzle, Power Generator, VFDs and associated equipment for effective washing of blades.

Designed 3D CAD model of Wind Turbine Blade Washing Rig on Design Software CREO with Piping and Instrumentation network on SOLIDWORKS.

Prepared all proposal-stage technical drawings including Mechanical and Electrical drawings for the entire project.

Estimated the required work force, materials, tools and equipment requirement for construction of the project and coordinated with the Planning Engineer in developing Primavera based plan.

Prepared BOQs in compliance with the design specifications and best practices for structures and piping scope of the work.

Prepared RFQs (Request for Quotations) for the procurement department after the market surveys.

Metrological MET Masts Project:

Designed structural model of Guyed Three Legged 80 meter Metrological Met Mast on Tower Numerics RISA Tower Software.

Conducted structural analysis of the tower in RISA Tower Software, including but not limited to derivation of tension values in Guy wires, foundation strength and sustainability of structure subjected to maximum wind shear in the region.

Coordinated with vendor in installation of the three Guyed Met Masts at site according to IEC 61400-12-1: 2005 standard for Power Curve Performance Test.

Prepared installation reports of three installed Metrological Met Masts at site according to the World Bank Installation Report of Metrological Met Masts for Wind Resource Mapping in Pakistan.

Operations and Maintenance Engineer

Ensuring a smooth transition of the plant from the construction phase to the operations phase.

Physical presence on all planned (Break in Maintenance, Semi-Annual and Annual Maintenance) and breakdown activities performed by the service team on GE 1.7-103 wind turbines both down tower and up tower.

Understanding diagnostics of faults in the GE 1.7 wind turbines and their rectification process with the help of schematics and Toolbox St.

Conducting routine surveillance of GE 1.7-103 Gearbox on ADAPT© Farm Client and drafting vibrational analysis report.

Running in-house Conditioning Monitoring System on GE 1.7-103 and intimating WTG service team about respective anticipated faults.

Maintaining record of WTG and BOP spare parts consumption and their replenishment in the WPO&M period.

Understanding of basics of Wind Power Plant, Grid interconnection, dispatch, contracts and annual revenue projections on Energy yields with respect to varying Tariff slabs in upfront tariff of Energy.

Handling Non-Project Events and calculation of billable/Non-Billable Missed Volumes as per energy purchase agreement (EPA).

Working knowledge of EPC, FSA, EPA, NTDC/NPCC sop’s, Plant Operating & HSE procedures.

Project Engineer

Owner’s Engineer for the installation of Pakistan's Largest Wind Power Plant of 150 MW (Tricon Boston Consulting Corporation Private Limited).

Coordinated with EPC contractor (Hydro-China) and its subcontractors in successful completion of the 150 MW Tricon Boston Complex in record time.

Design:

Managed, monitored and interpreted the EPC Contract, its schedules and related contract design documents.

Reviewed Wind Turbine installation and commissioning related documents including but not limited to Work Instructions Sheets, Quality Inspection Plans, Method of statements and Technical papers etc.

Reviewed Wind Turbine equipment unloading and lifting plans/drawings on site.

Reviewed vendors’ specifications and design of the complex.

Helped EPC Contractor in resolving unexpected technical difficulties and critical issues in design phase that could delay the progress of the project in the practical phase.

Installation and Commissioning:

Monitored EPC contractor (Hydro-China) and its subcontractors for the installation and commissioning of 87 GE 1.7-103 wind turbines and Fire Fighting System at three substations as per protocols of EPC Contract.

Engaged with EPC Contractor to ensure efficient planning of installation and commissioning of 87 GE 1.7-103 wind turbines and Fire Fighting System.

Monitored unloading and lifting activities of Wind Turbine components and other WTG component preparation activities at site.

Monitored the timely availability of heavy load cranes and other required components/tools for the installation and commissioning.

Attended site inspection calls for Wind turbine Blades, Towers, Nacelle, Hub, down tower assembly, Anchor foundation bolts and their installation.

Coordinated with GE team in entire Turbine assembly, Generator alignment , IIP (Installation Inspection Procedure) and final CCT (Converter Commissioning Test) by climbing the turbine.

Intern

Studied in detail American Petroleum Institute manuals of thermodynamic devices : pump , compressors , turbines , heat-exchangers and valves.

Hands on experience in maintenance of thermodynamic devices in mechanical workshop.

Got exposure about the manufacturing and packaging of UREA

Intern

Got exposure and hands on experience in construction of Gas Sweetening Plant.

Hands on experience in non-destructive tests for quality assurance.

Learnt visualizing PIDs and hands on experience in carrying out welding.

Worked with maintenance department of Client company OGDCL.

Visited unsweetened natural gas wells with the maintenance team of OGDCL.