خلاصہ

I am a mechanical engineer who's well-versed engineer with a diversified experience in the fields of supply chain, production planning, and project & maintenance operations. Endeavoring to expand my profession with a multi-national company having high-growth and professional development culture. I keep up-to-date with the latest materials and techniques.

پراجیکٹس

تجربہ

Production planner and material controller

Assist and report GM plant regarding plant operations and supply chain activities

Determining, implementing and monitoring production strategies, policies and plans

Make recommendations for improvement to work process. Contribute to 5S program in work place

Monitoring production output and costs, and adjusting processes and resources to minimise costs

Work closely with floor incharge to make and monitor schedule on Microsoft Excel

Work with manufacturing manager to track production performance and develop process

Inventory management of raw material and equipment required for maintenance and production

Material planning and procurement for in-house projects and production

Strategy development and planning for in-house projects, maintain and control project plan schedules

Forecasting and scheduling of monthly preventive maintenance plan, its reporting and analysis

Assistant Manager Production Planning & Material Control

Assist and report GM plant regarding plant operations and supply chain activities

Collaborate with Sales, Operations, and Customer Service teams

Provide input and feedback to management regarding schedule performance

Implement and manage systems which improve efficiency and activity

Oversaw material goods and equipment inventories and accountability

Managed all material planning efforts along with direct oversight of all International and Domestic procurement.

Established Receiving Inspection Dept., Inventory/Cycle Count programs, & warehouse re-layout improving material flow

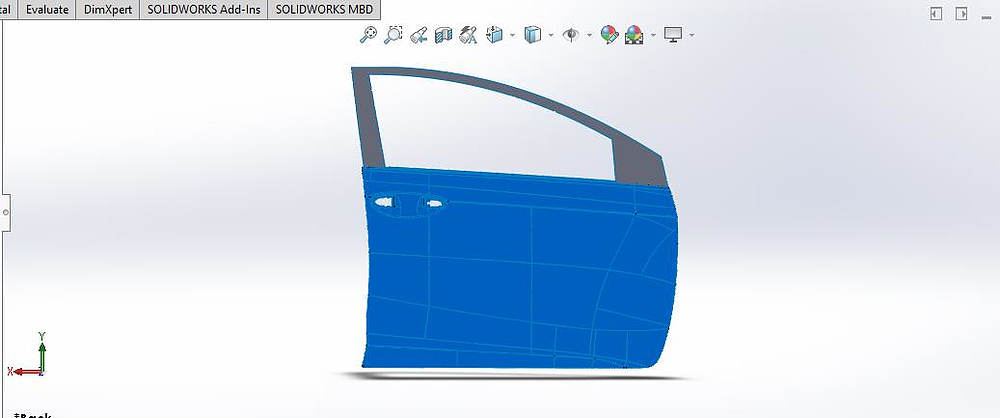

Development Engineer

RESPONSIBILITIES:

• Update new development status.

• OEM follow up for new developments.

• Fulfil testing requirements of newly developed parts.

• Follow up mold maker for under developed molds.

• Monitoring daily production.

• maintain all data for RFQ to mass production.

REPORTS GENERATED BY ME:

• Daily & Monthly production analysis.

• Development achievement on monthly basis.