خلاصہ

A resourceful and accomplished individual with approximate 5 years of comprehensive experience in Mechanical Engineering. Very effective in providing detailed feasibility report study, Project management, Estimation and Engineering Design support compliant to Department’s mission and procedures. To obtain a position that will enable me to gain experience and develop my skills and knowledge in a people-oriented organization.

پراجیکٹس

تجربہ

Shift Engineer

Mill House Auxiliary Chain and Main Chain Working on Five Number of mills with Turbines Leveler Chopper Fibrizer Rake Carrier Feed Pump F.D Fan Belt Conveyor and Magnetic Seprator Worm Gear Corn Gear Spur Gear Look after of Economiser Air Pre-Heater BoilerPump Fan Motors Cooling towers

Assistant Manager

Assistant Manager MEP 2019 Pres.

Commissioning of fire water system

Commissioning sewage treatment plant

Lead new equipment commissioning in the production plants and train the

production teams

Mechanical engineers will work on problems of diverse scope where

analysis of data requires evaluation of identifiable factors in HVAC systems,

plumbing systems, and fire protection systems.

Increase production, assets capacity and flexibility while minimizing unnecessary

costs and maintaining quality standard.

Reduce maintenance cost of all the machinery installed in the plants / warehouses

of the company.

Collect and analyze data, putting together production reports for both

factory managers and customer

Elect equipment and take responsibility for its maintenance

Carry out routine maintenance work and respond to equipment faults

diagnose breakdown problems

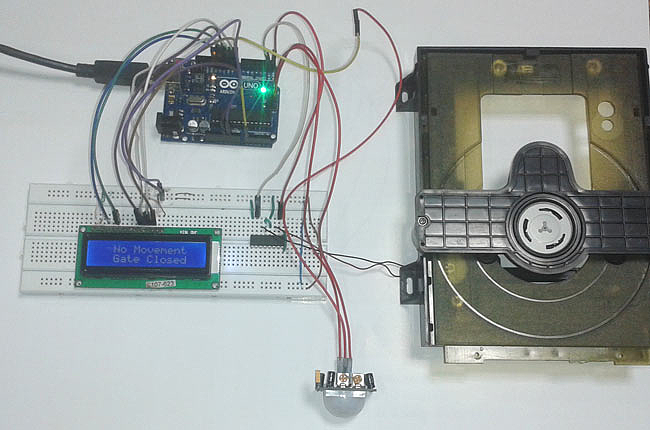

Work with specialist equipment, such as programmable logic controllers

(PLC), which control machinery on factory assembly lines

Evaluate current production activities and make recommendations for

improvements.

Stay current with product specifications, engineering technology and

production processes.

Establish safety procedures and environmental regulations for employees.

Provide engineering support for production and maintenance activities to

ensure maximum production.

Maintenance Engineer

Mechanical Engineer 20172019

Develop new projects/conduct strategic planning for business initiatives,

from inception to implementation.

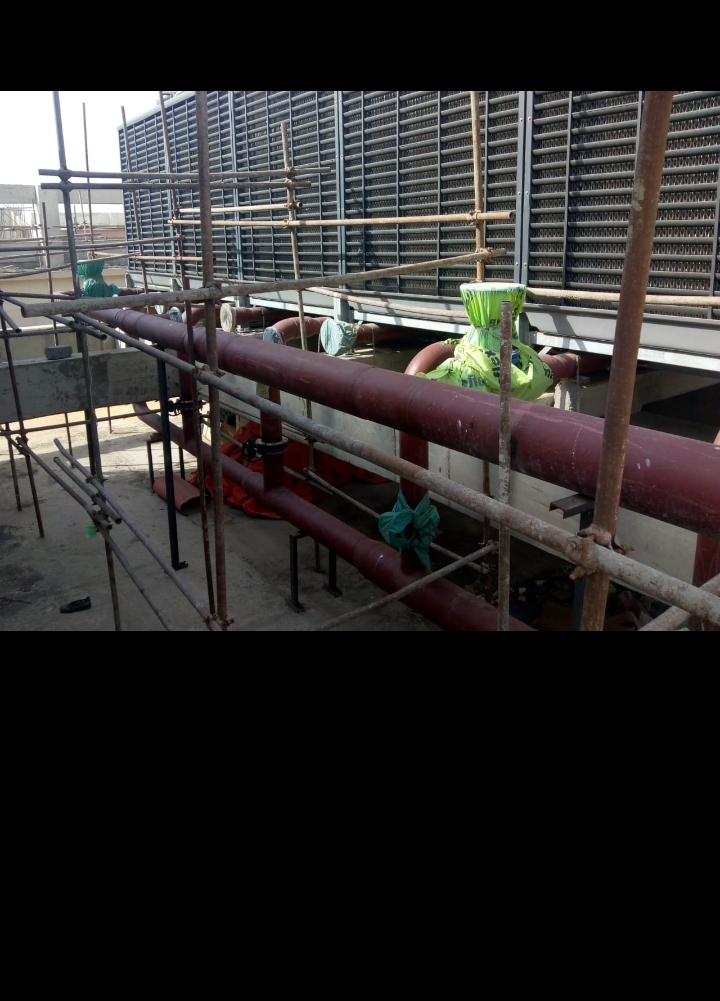

Execution Commissioning and Maintenance of External-Internal and

Drought Type Cooling Tower

Execution Commissioning and Maintenance of Air- & Water-Cooled Chiller

Execution Commissioning and Maintenance of AHU and HVAC Equipment

Execution Commissioning and Maintenance of Fire Pump and Boiler

Calibration of Pressure Gauges and Temperature Gauges

Drafting process ideas to reduce costs and improve production rates.

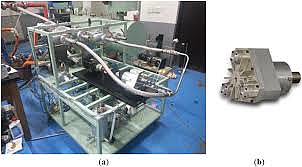

Maintenance and Calibration Engineer

Maintenance and Callibration Engineer at premier tubular inspection service , have to maintain the equipment and have to callibrate the equipment of oil and gas company

Intern

Winter Internship for a period of three weeks. Analyzed the layout of power generation cycle incurring in 4 power units developing the net total of 800 MW electricity together with the refrigeration chillers operating on vapor absorption cycle using the steam extracted from Low stage turbine.

Intern

Perform engineering work related to configuring, deploying, maintaining and upgrading CAD models.

Design, develop and engineer high quality models using 3D and 2D CAD tools.

Produce designs that meet targets for feasibility, performance, costs, quality, safety, legislation and timing.

Ensure that all work carried out is in compliance with company design, safety, quality, environmental compliance and proceduralstandards

trainee Engineer

I was trainee there to work with machines and fabrication process

Intern

Two Week Winter Internship

Tutorial and workshop sessions to address the design, operation and maintenance of boilers, as well as boiler theory

Operational and maintenance issues associated with extraction plant, extraction processes, terminology and measurement techniques

Work out on Efficient Use of High Pressure and Process Steam

Extraction Theory and Practice for Milling Engineers

Introduction to Extraction for Shift Supervisor

Steam Generation