خلاصہ

My current goal is to obtain a challenging position in Engineering industry where my resourceful experience and academic skills will add value to organizational operations, customers and as well as society.

پراجیکٹس

تجربہ

Assistant Manager-Projects & Development

Responsibilities

Training of workers about the best practices of operating the machines and ensuring its implementation.

Conduct training sessions about HSE which included hazard identification, 5S and material handling.

Maintaining the quality control data of both customer and in-house rejections.

Making daily root cause reasons of in-house rejection and monthly customer rejections.

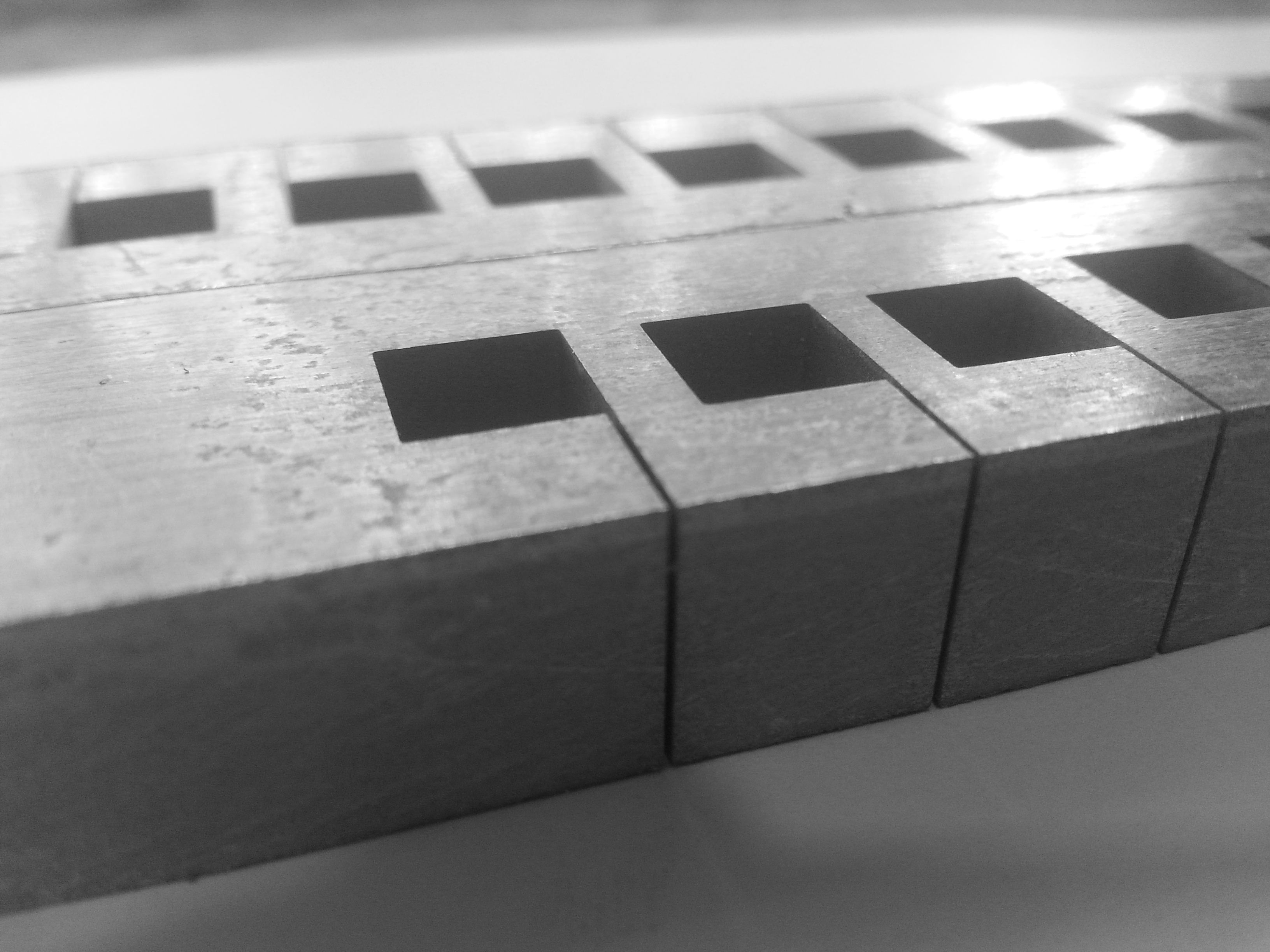

Setting of gear ratios of “Hobbing Machines” at every new type of product.

Product design and development before every new product which included process sheets, CAD/CAM and quality sheets.

Sampling of products at final stage before dispatch and analyze them through quality control sheets.

Run weekly maintenance program of “Timing Gear Machines” which included “Preventive” and “Corrective” maintenance.

Projects Completed

Developed a Value Stream Map for “Timing Gears” production line for the reduction in “Manufacturing Lead Time”.

Made optimum machine layout for a new manufacturing line.

Overhauling of “Gear Grinding Machine” from the aspect of its hydraulic system.

Time study of “Fly Wheel Gear” production line to calculate the standard time of piece produced by worker.

Designed foundation for 20 ton “Gear Grinding Machine” to reduce its vibration during operation.

Engineering Intern

-Designed the optimize layout of a section hall on Auto CAD 2010 for the placement of new machine.

-Developed the feasibility report of replacing “guillotine cutter” with “band saw cutter” in order to cut tissue paper bulks.

-Root Cause Analysis of “Sealing mould of paper cup machine” that was not working properly.

-Designed special operation table for “band saw cutter” on Auto CAD & Solid Works.

Engineering Intern

-Developed the understanding of some Sheet Metal processes in the manufacturing of aircraft.

-Observed the working of different types of CNC milling machines with maintenance point of view.

-Perform Finite Element Analysis and make adjustments to tool surfaces to guarantee part quality.

Engineering Intern

-Worked on the overhauling of 12 cylinder diesel locomotive’s engine.

-Analyzed comprehensively the hydraulic system of diesel locomotive.

-Developed the understanding of foundry processes.