خلاصہ

2. JOB PURPOSE

Responsible for managing all kind of organizational Mechanical matter. Provide

guideline to team to ensure proper timely working.

3. ESSENTIAL KEY ACCOUNTABILITIES

1- Assist Manager Admin Management in accomplishing

Annual Strategic Plan regarding changes in the

mechanical domain ANNUAL

PLAN 2- Align with departmental activities with department

Strategic plan for extensions, improvements or installation

of matters related to mechanical area.

3- Ensure timely resolution of all kind of Mechanical work.

4- Ensure that all kind of equipment's is available for efficient

completion of mechanical work.

5- Ensure proper efficient use of all mechanical items

available in workshop to avoid any damages

6- Took necessary actions to ensure that all security

parameters have been taken while in working mode.

7- Ensure implement all compliance SOP in mechanical

department.

8- Ensure proper implementation of mechanical roaster for

overall Inspection of mechanical equipments/Machinery.

9- Maintain mechanical departmental details for each month

for future budget analysis forecasting.

10- Must know how to follow sop's while installing of new

equipments /Machinery.

11- Coordinate help departments on all kind compliance

matters related to mechanical.

Compliance 12- Timely resolve all kind of internal compliance audit NC's.

13- Ensure working according to compliance rules and

regulations.

14- Ensure proper documentation to tract the Complain

handle time to revise the steps to enhance the efficiency STRATEGIC Mechanical work

Management Ensure Complain Trouble shoot of complain handling Time

15- Troubleshoot the faults in any machine and also solving

its problems in the minimum time period.

16- Well versed with operation maintenance of mechanical

equipments/ Tools

17- Must know how to operate machinery in the mechanical

shop i.e. drilling m/c, welding, gas cutting etc.

18- Well versed with f

پراجیکٹس

تجربہ

Assistant Manager

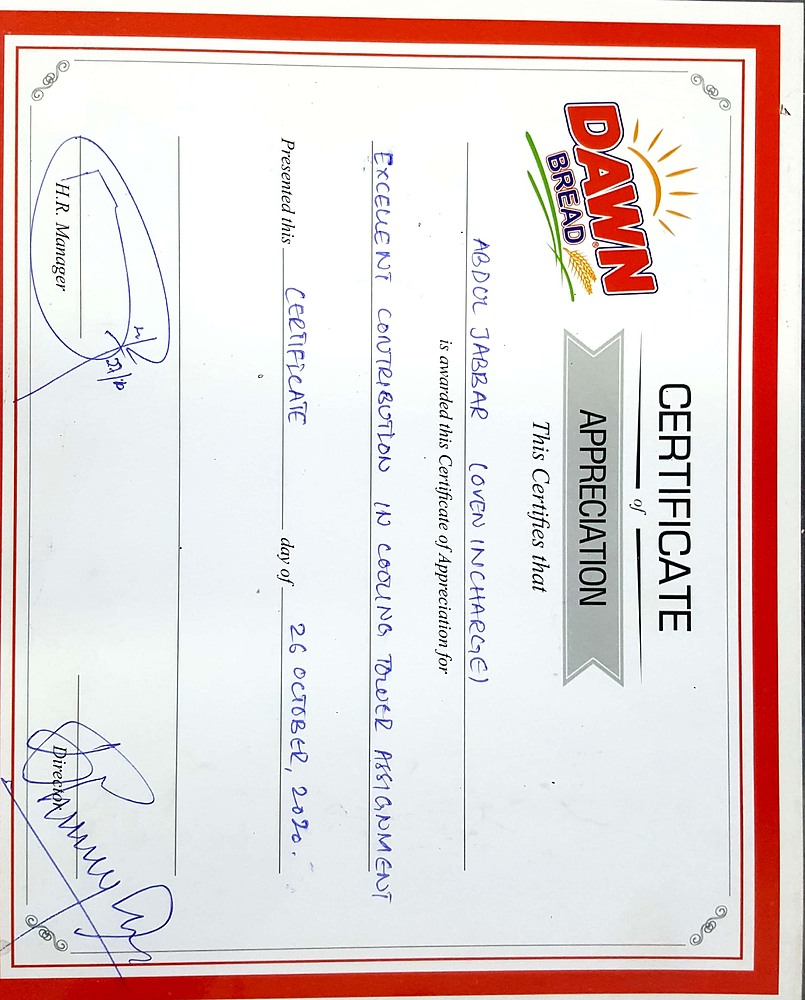

Experienced Assistant Manager Mechanical maintenance with demonstrated history of working in the Biscuits,Bread, Pharmaceutical, Colours & Chemicals & Sugar industries industry.

☆Establish maintenance goals including mechanical, electrical and utilities program in accordance with Head Office goals and give direction to team members to align with departmental goals considering EHS, PQS and corporate compliance requirements.

☆ Develop preventive maintenance program and calibration program to maintain plant and utility equipment in coordination with production and other stakeholders to support uninterrupted operation.

☆ Explore competent vendors and fabricators for equipment, parts, spares, operation, and maintenance activities.

☆ Ensure efficient and cost-effective maintenance activities well within approved budget to meet a key KPI.

☆ Responsible for the planning of routine and non-routine maintenance work in efficient and cost-effective manner, Coordinate with Quality Assurance & procurement team to align with current expectations.

☆ Support engineering store for maintaining sufficient inventory of critical spares and supplies.

☆ Review the daily performance of the team members in well documented manner to ensue performance management of each team members are being monitored and assessed in line with established goals and site expectations. Ensure all the work orders are addressed and closed in SAP well in defined timeline.

☆ Responsible to ensure that all the required standard operating procedures are developed and effective.

☆ Ensure that all the activities are being managed in accordance with applicable procedures with maintenance.

Hand on experienced in following equipments

Expertise in operating, Maintenance of Tunnel ovens having dual fuel burnors (J4, Helix,WP etc) & rack ovens.

BISCUITS LINES MULTIPLE CAPACITY, BREAD MANUFACTURING LINES AT MULTIPLE CAPACITY,

GRINDING PROCESS, PET BOTTLE RECYCLING PROCESS, EXTRUDER LINES, PAINT MANUFACTURING EQUIPMENS, ABSORBTION CHILLERS, WATER CHILLERS, COPRESSION UNITS, BOILING PROCESS, BLOWING MACHINES, TABLET COMPRESSION MACHINES, BLISTER PACKING MACHINES, COATING, FILLING,CAP SEALER, CORTON PACKING, LABELING MACHINES, AHU,DEHUMIDIFIER, COOLING SYSTEMS

RO PLANT, BOILER, CHILLERS, GENERATOR, AIR COMPRESSOR ,COOLING TOWERS, MIXERS, SLICERS, PACKING MACHINES, PROOFER

DYNAMIC/STATIC EQUIPMENTS

Assistant Manager

Responsible for Operation, Installlation & Maintenance of Plant Equipmets & Utilities

Engineering Incharge

Managing the Plant or projects related to installation, maintenance and operation. Throughout the course of my career, I have perfected my maintenance, operation and installation abilities. I am a capable and consist problem-solver skilled at prioritizing and managing projects with proficiency. In my previous role, I contributed decision-making, communication and managing towards team efforts and business improvements. I am progressive minded and in tune with new developments in my field. I have proven to be effective and collaborative with strong critical thinking talents.

Mechanical Incharge

Mechanical Incharge

Incharge Mechanical & Electrical

Assistant Engineer

Technical supervisor

Technical Supervisor

Technician

Apprintus technician