خلاصہ

Highly motivated and dedicated Mechanical Engineer seeking a challenging position in a progressive company where I

can apply my strong technical skills and knowledge to contribute to the design, development, and optimization of mechanical systems

پراجیکٹس

تجربہ

Mechanical Site Engineer

As a Mechanical Site Engineer on Garden Residence Project i am supervising installation, testing and commissioning of Ducting, Plumbing,Fire fighting and VRF systems.

Monitor daily site activities to ensure progress according to schedule.Ensure safety protocols are followed.Inspect work quality to meet required standards of ASHRAE and SMACNA.

Prepare progress reports for site activities.Maintain documentation related to installations, material orders, and inspections.

HVAC Site Engineer

Since 2006, MA Engineering Services Intl has been dedicated to delivering top-notch equipment and services for HVAC systems.

During my tenure as an Mechanical site engineer on a canal project near Muslim Town in Lahore, I undertook various responsibilities-I meticulously performed load calculations and meticulously designed HVAC system layouts, encompassing detailed ductwork and piping design. I actively participated in on-site meetings, collaborating with the team to engage in review discussions and diligently report any issues identified at the site.

I was responsible for compiling and distributing daily OCR, NCR, and progress reports, as well as labor attendance records, which significantly contributed to a 15 improvement in project tracking accuracy and team accountability. I adeptly utilized CAD software such as AutoCAD and Revit to draft and modify HVAC as-built drawings, ensuring precision and accuracy in the project's design and implementation.

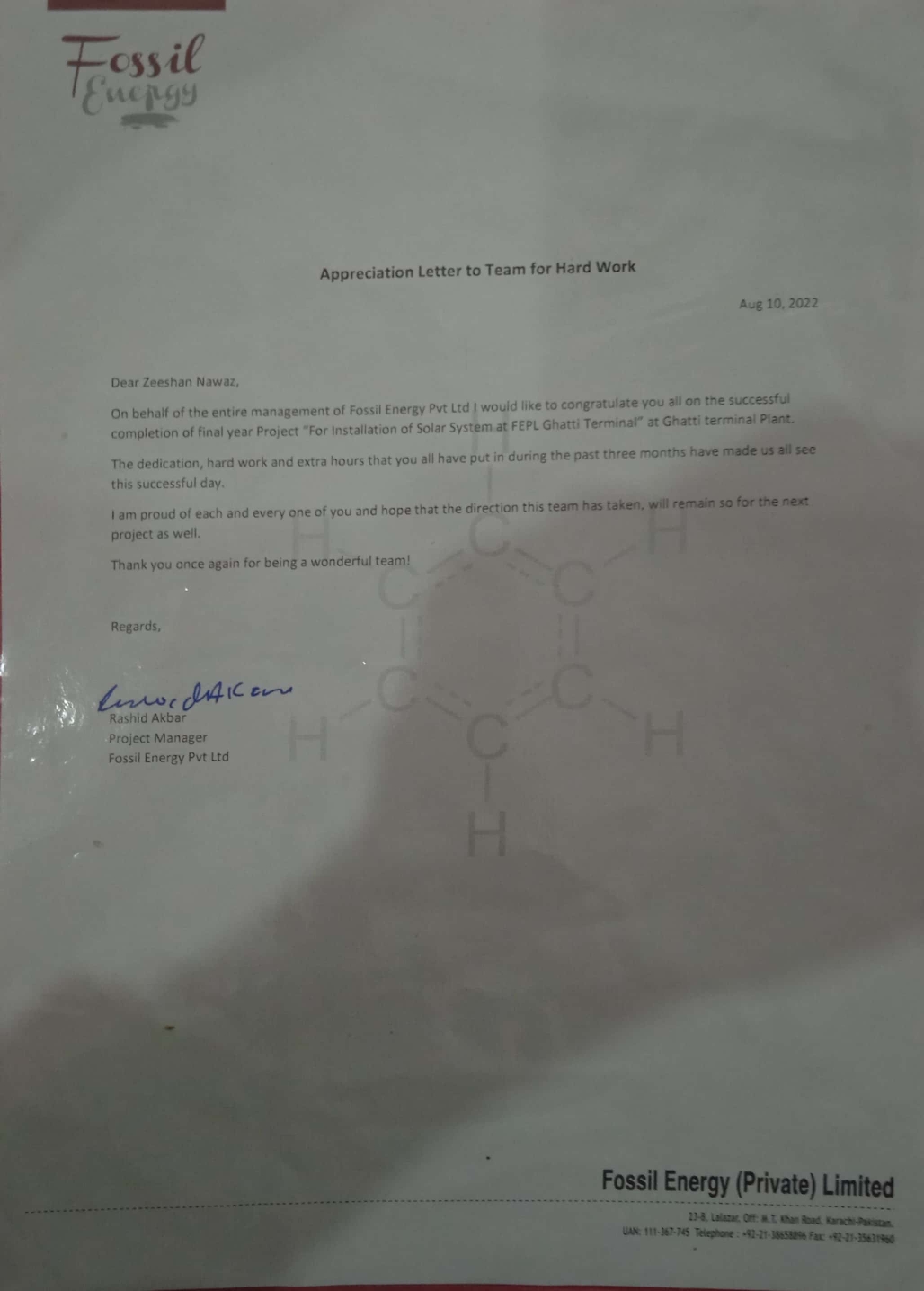

FYP Project Intern

FEPL plans to explore the possibility of having a captive (in-house) renewable energy system which can provide either operational or non-operational electrical load requirements through renewable sources.Calculation of Operational and non-Operational loadProposing the best possible renewable energy source system applicable on siteBill of quantities calculationCalculation of pay back durationSuccessfully contributed to my Final Year Project with the firm, showcasing my ability to apply theoretical knowledge to practical applications.

Trainee Mechanical Engineer

Understanding the principles, performance characteristics, and operation of gas turbines used in combined-cycle power plants. Familiarizing oneself with the design, operation, and maintenance of steam turbines used in combined cycle power plantsGaining knowledge about HRSG systems, which capture waste heat from the gas turbine exhaust and produce steam to drive a steam turbine.Acquiring knowledge about the design and layout of piping systems that transport fluids, including steam water, and fuel, throughout the power plant.Learning about various auxiliary systems, such as cooling water systems, fuel supply systems, lubrication systems, and control systemsUnderstanding safety protocols, risk assessment, and environmental regulations relevant to combined cycle power plantsProduce technical reports and equipment manuals